Are you considering a career in the industrial sector?

Delving into welding training as a beginner can be a transformative step towards unlocking a world of opportunities within various industries.

11 Reasons To Give Welding Training For Beginners

1. Lucrative Career Opportunities:

The industrial sector is a bustling hub of activity, offering a multitude of job opportunities for skilled welders. From manufacturing plants and construction sites to oil refineries and shipyards, the demand for welders is ever-present, promising competitive salaries and potential for career advancement.

2. Safety Compliance:

Safety is paramount in the industrial environment, and welding training instils essential safety protocols to ensure compliance with industry standards and regulations. By learning how to identify potential hazards and mitigate risks, beginners can create a safer work environment for themselves and their colleagues.

3. Skill Enhancement:

Beginner welding training programs provide a comprehensive foundation in welding techniques tailored specifically for industrial applications. From mastering various welding processes like MIG, TIG, and stick welding to understanding metal properties and joint preparation, training equips beginners with the skills needed to excel in the industrial setting.

4. Industry-Specific Knowledge:

Industrial welding encompasses a diverse range of applications, each with its unique challenges and requirements. Welding training offers insights into industrial welding practices, materials, and equipment, enabling beginners to tackle real-world scenarios with confidence and competence.

5. Certification Validation:

Completing welding training and obtaining industry-recognized certifications validate beginners’ skills and competencies, enhancing their credibility and employability within the industrial sector. Employers value certified welders who demonstrate proficiency and commitment to their craft.

6. Hands-On Experience:

Practical exercises offered in welding training programs allow beginners to gain invaluable hands-on experience in industrial welding scenarios. Through supervised practice sessions, learners can refine their welding techniques, develop their problem-solving skills, and build the confidence needed to succeed in the field.

7. Adaptability Across Industries:

Welding skills acquired through industrial training are highly transferable across various sectors, including manufacturing, construction, automotive, aerospace, and more. This versatility widens career opportunities for beginners, allowing them to explore different industries and pursue diverse career pathways.

8. Career Advancement Prospects:

With continuous skill development and certifications, beginners can advance their careers within the industrial sector. Whether it’s pursuing specialized roles, taking on leadership positions, or transitioning into supervisory roles, welding training lays the groundwork for career growth and increased earning potential.

9. Precision and Quality Assurance:

Industrial welding demands precision and quality to meet stringent industry standards and specifications. Training emphasizes the importance of precision welding techniques and quality assurance practices, ensuring that beginners can deliver superior workmanship that meets or exceeds industry expectations.

10. Collaboration and Teamwork:

Welding often involves collaboration with other professionals, including engineers, designers, and fabricators, in industrial settings. Training fosters teamwork skills, communication, and collaboration, preparing beginners to work effectively in multidisciplinary teams to achieve common goals and objectives.

11. Future-Proof Skillset:

Welding remains an essential trade in the industrial sector, offering long-term stability and demand even in the face of technological advancements and economic fluctuations. By investing in welding training, beginners acquire a future-proof skillset that remains relevant and in demand across various industries for years to come.

In summary, welding training for beginners in the industrial sector provides a pathway to lucrative career opportunities, safety compliance, skill enhancement, and career advancement. With industry-specific knowledge, hands-on experience, and certifications, beginners can embark on a rewarding journey in the dynamic world of industrial welding, where their skills are valued and in high demand.

Welding Training for High School Students: Building a Strong Foundation

High school is an opportune time for students to explore their interests and gain exposure to potential career paths.

Welding training programs designed for high school students offer a structured approach to learning the basics of welding and understanding its various applications. These programs often include:

1. Classroom Instruction:

Students receive theoretical knowledge about welding processes, safety procedures, types of welding equipment, and the properties of different metals.

2. HandsOn Practice:

Practical training allows students to work with welding equipment, practice different welding techniques, and gain proficiency in creating strong and durable welds.

3. Certifications:

Some high school welding programs offer the opportunity to earn industry-recognized certifications, such as those from the American Welding Society (AWS). These certifications validate students’ skills and enhance their employability.

4. Career Guidance:

Experienced instructors provide insights into the various career paths within the welding field, helping students make informed decisions about their future.

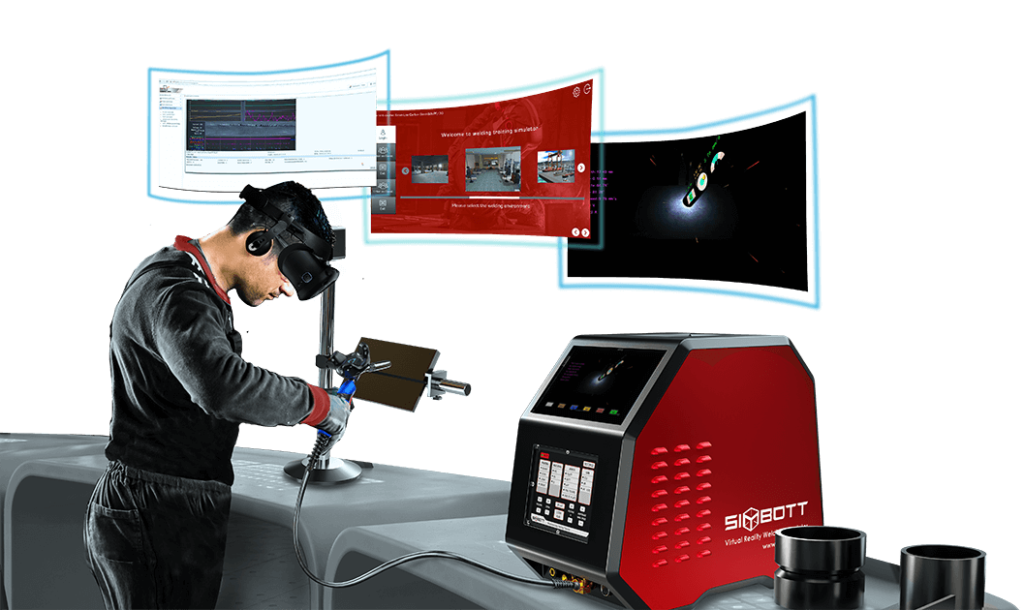

How to Use Using AR/VR Welding For Training?

As technology continues to reshape education, augmented reality (AR) and virtual reality (VR) are finding their way into the world of welding training. These immersive technologies offer unique advantages for high school students

Today, high school students can safely and effectively learn welding using augmented reality and virtual reality welding simulators.

These advanced technologies offer a realistic training experience without the risks associated with live welding, allowing students to practice and refine their skills in a controlled virtual environment.

Integrating these simulators into welding education programs enhances the learning process, ensuring that students gain essential skills before transitioning to actual welding tasks.

This innovative approach prioritizes safety while optimizing the training of the next generation of welders.

See Our Complete Welding Training Product For High-School Students – VR Welding Simulator

Follow Our Simple Process:

- Introduction to AR/VR:

Familiarize students with AR and VR welding simulation technology, explaining its relevance to real-world welding practices. - Equipment Familiarization:

Ensure students are comfortable using AR and VR devices, providing hands-on training for headsets and controllers. - Safety Protocols:

Emphasize safety procedures within the virtual environment, mirroring actual welding precautions. - Basic Welding Skills:

Start with fundamental welding techniques in the virtual space, covering essential skills like electrode handling and torch control. - Progressive Complexity:

Increase task complexity gradually to challenge students as they gain proficiency, incorporating diverse welding scenarios. - Feedback and Assessment:

Implement real-time feedback within simulations to assess and improve students’ performance continuously. - Scenario-Based Training:

Introduce scenario-based training to simulate diverse welding environments and challenges. - Collaborative Learning:

Foster teamwork by incorporating multiplayer features in the simulators, encouraging shared problem-solving. - Industry-Relevant Content:

Include content aligned with industry standards, procedures, and codes to prepare students for real-world applications. - Practical Application:

Bridge virtual training with hands-on experiences, allowing students to apply their skills using actual welding equipment under supervision.

FAQ’s

What is the duration of welding training programs for beginners?

The duration of welding training programs can vary depending on factors such as the level of expertise desired, the intensity of the program, and the training provider. Generally, beginner-level welding training programs may range from a few weeks to several months.

What types of welding processes are covered in beginner welding training programs?

Beginner welding training programs typically cover fundamental welding processes such as MIG (Gas Metal Arc Welding), TIG (Gas Tungsten Arc Welding), and stick welding (Shielded Metal Arc Welding). These processes form the foundation of welding skills and are essential for beginners to master.

What career opportunities are available to individuals who complete beginner welding training programs?

Completing a beginner welding training program opens up various career opportunities in industries such as manufacturing, construction, automotive, aerospace, and more. Graduates may pursue roles as welders, fabricators, pipefitters, and metalworkers, or pursue further education and certifications for specialized roles.

Are there any age or educational requirements for enrolling in welding training?

While age and educational requirements may vary depending on the training provider and local regulations, many welding training programs welcome students of all ages and educational backgrounds. Some programs may require participants to have a high school diploma or equivalent.

Final Thoughts:

In summary, welding training for beginners in the industrial sector provides a pathway to lucrative career opportunities, safety compliance, skill enhancement, and career advancement.

With industry-specific knowledge, hands-on experience, and certifications, beginners can embark on a rewarding journey in the dynamic world of industrial welding, where their skills are valued and in high demand.